Products

Professional Use

Filled Epoxy Resin Adhesive for Civil Engineering

Anchor bolt filler for horizontal set.

Various anchors and bolts fixing and bonding.

Features

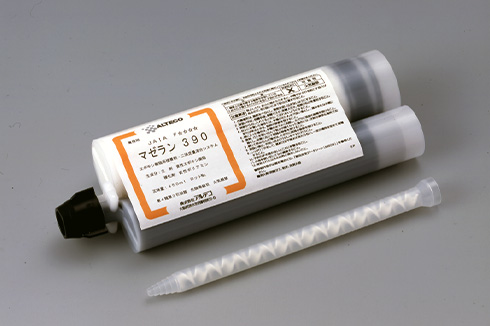

MAZERUN 390

Direct application to wall surfaces.

Highly thixotropic - no sag.

No debubbling, sealing.

Excellent working efficiency in cartridges.

Eliminating measuring process - time saving.

Ensure the main part and the hardener mixing.

Applicable on wet surfaces.

Solvent-free and contains no volatile components.

Minimal shrinkage after curing.

Low VOC / Formaldehyde Emission

Compliant with JAIA F★★★★ and 4VOC standards – Japan’s strictest safety criteria for indoor air quality.

Suitable for use in living spaces requiring low chemical emissions.

Properties

| MAZERUN 390 | ||

|---|---|---|

| Base Resin | Hardener | |

| Main Component | Modified Epoxy Resin | Modified Polyamine |

| Appearance | White Grease | Black Grease |

| Mixing Ratio (by Volume) | 2:1 | |

| Pot Life at 20℃ | 20min | |

Cured Material Properties

| Unit | Internal Standard | Test Procedure | |

|---|---|---|---|

| Specific Gravity | – | 1.15±0.15 | JIS K 7112 |

| Compressive Yield Strength | N/㎟ | ≧70 | JIS K 7181 |

| Compressive Modulus of Elasticity | N/㎟ | ≧1.5×103 | JIS K 7181 |

| Bending Strength | N/㎟ | ≧50 | JIS K 7171 |

| Tensile Strength | N/㎟ | ≧30 | JIS K 7113 |

| Tensile Shear Strength | N/㎟ | ≧16 | JIS K 6850 |

| Hardness | HDD | ≧80 | JIS K 7215 |

| Impact | kJ/㎡ | ≧3.0 | JIS K 7111 |

Test temperature: 20℃

Anchor Bolt Installation Example

| Deformed Bar (D) Bolt Size (M) |

Hole Diameter (㎜) | Hole Depth (㎜) | Required Resin Amount (g) | Number of Applications per Set (pcs) | Yield Point of Steel (kN) | Allowable Tensile Stress (kN) | |

|---|---|---|---|---|---|---|---|

| 450ml | 900ml | ||||||

| D6 | 10.0 | 50 | 3 | 177 | 354 | 10.9 | 7.3 |

| D13 | 19.0 | 110 | 22 | 24 | 48 | 43.7 | 29.1 |

| D19 | 25.0 | 150 | 38 | 14 | 27 | 98.8 | 65.9 |

| D25 | 32.0 | 200 | 74 | 7 | 14 | 174.8 | 116.5 |

| D29 | 35.0 | 290 | 116 | 4 | 9 | 221.6 | 147.8 |

| D32 | 42.0 | 320 | 236 | 2 | 4 | 274.0 | 182.7 |

| D35 | 45.0 | 350 | 277 | 2 | 4 | 330.0 | 220.0 |

| M8 | 9.5 | 70 | 3 | 173 | 345 | 8.6 | 5.7 |

| M12 | 14.5 | 100 | 10 | 51 | 103 | 19.8 | 13.2 |

| M16 | 19.0 | 130 | 21 | 25 | 50 | 36.9 | 24.6 |

| M18 | 22.0 | 150 | 35 | 15 | 29 | 45.1 | 30.1 |

| M22 | 28.0 | 180 | 70 | 7 | 15 | 71.2 | 47.5 |

| M24 | 32.0 | 240 | 135 | 4 | 8 | 83.0 | 55.3 |

| M27 | 36.0 | 270 | 188 | 3 | 5 | 107.9 | 71.9 |

●The yield point of the rebar steel is the value obtained by multiplying the nominal cross-sectional area by the reference strength of SD345, 345 N/mm².

●The yield strength of the steel for the full-thread bolt is the value obtained by multiplying the base strength of SS400, 235 N/mm², by the effective cross-sectional area.

●Do not use for items with smooth surfaces, such as round bars, which may not exhibit sufficient strength.

●The number of applications per set (pcs) is approximate.